Ceramic sand for foundries # lost foam

Model No.︰Mesh 25-35

Brand Name︰KAILIN

Country of Origin︰China

Unit Price︰US $ 490 / MT

Minimum Order︰1 MT

Product Description

Product Description

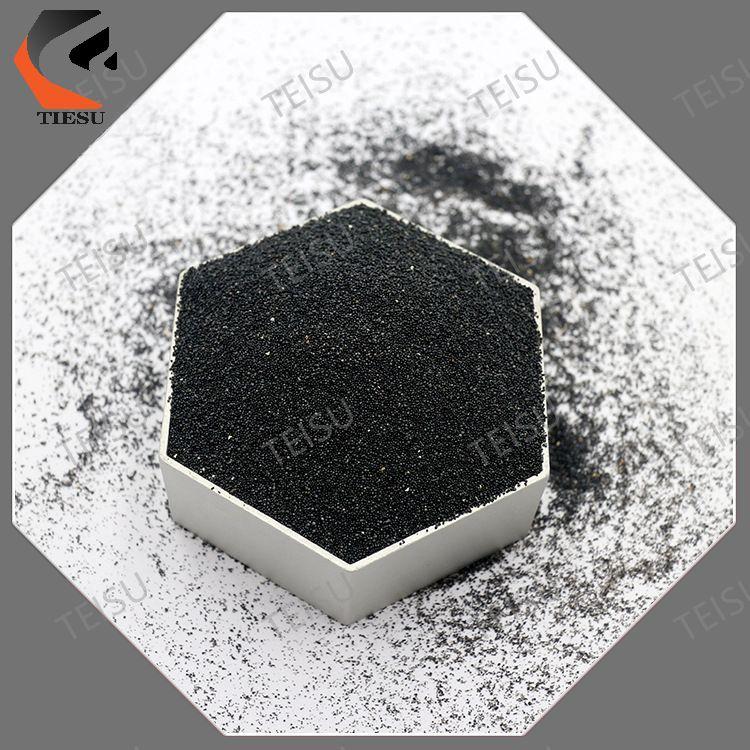

Mesh20 Mesh30 Mesh40 Fused foundry partical ceramic sand;Ceramic sand (ceramsite sand)is an advanced substitute for quartz sand in the casting field. Ceramic sand is made from calcined bauxite with the main content of aluminum oxide processed by melting, blowing, sieving and blending. After melting calcined bauxite with 65-90% aluminum oxide in a high-temperature electric arc melting device, the outflow of ceramic blown into fine particles. Then after cooling and sieving, the ceramic sand become finished particles with different size grade.

Characters

1.Low thermal expansion coefficient

2.High strength with good compressive strength and bending resistance ability and low broke rate.

3. spherical shape, good flowability, easy to shakeout

4. smooth surface, compact structure

5. chemically neutral material

6. high-temperature resistance, good refractoriness

7. Recycle up to 10 times, highly cost-effective.

8. Save resin consumption with casting tech such as shell molding, Resin coated sand casting, Vacuum casting, etc.

Typcal Chemicals

AL2O3 70-75%

SiO2 8-20%

Fe2O3 ≤3%

TiO2 ≤3.5%

CaO ≤0.45%

MgO ≤0.35%

K2O ≤0.33%

Na2O ≤0.08%

Typical Physical Properties

Refractoriness ≥1700 ℃

Specific gravity: 3.4g/cm3

Bulk density(LPD): 1.95-2.05 g/cm3

Color: black brown

Grit shape: spherical ball

Thermal expansion coefficient 6x10-6 /℃(20-1000℃)

Thermal conductivity 0.698W/M.K(1200℃)

Thermal expansion ratio 0.0013

Angularity ≤1.1

Applications

1.Shell molding

2.Precision Casting

3.Lost foam casting

4.Heavy steel casting

5.Resin coated sand casting

6.Vacuum casting

7.Investment casting

For more foundry materials and devices,please visit our website: http://www.tiesumachinery.com

Payment Terms︰ TT

Product Image